Encoris Helps You Reach Your Product Launch Goals

Increasing Medical Device Adoption Success

Encoris is the Industry Leader

Better Technical Skills Development

With medical education’s heightened demand for better technical skills development and desire for better decision-making, proficient surgical education equips medical device companies, their sales force, and their surgeon clientele with greater competence and confidence necessary to promote and deliver higher-quality surgical implant and procedural outcomes.

Medical device companies with solid surgical training and education protocols foster a deeper sense of responsibility and commitment to lifelong surgeon-patient education, contributing to advancements in surgical care and medical science.

Why Encoris for Surgical Training Education

Encoris, located in Holland, Michigan, manufactures industry-leading medical models and surgical skills trainers for global clients like Stryker, Zimmer Biomet, and Medtronic.

Encoris’ CAD design capabilities and product development expertise accelerate manufacturing output, producing the fastest lead times in the industry.

Speed to market and anatomical accuracy are important to our medical device clients. Our transparent communication and manufacturing processes provide clients peace of mind that allows you to:

- Achieve surgical training demands and business objectives

- Launch new medical device technologies on time

THE BOTTOM LINE

Encoris’ customized surgical education and training products greatly enhance and promote a medical device’s key features and benefits, bringing about greater understanding -greatly benefiting a medical device company’s surgical skills training, sales-rep-to-surgeon, and surgeon-patient interaction goals.

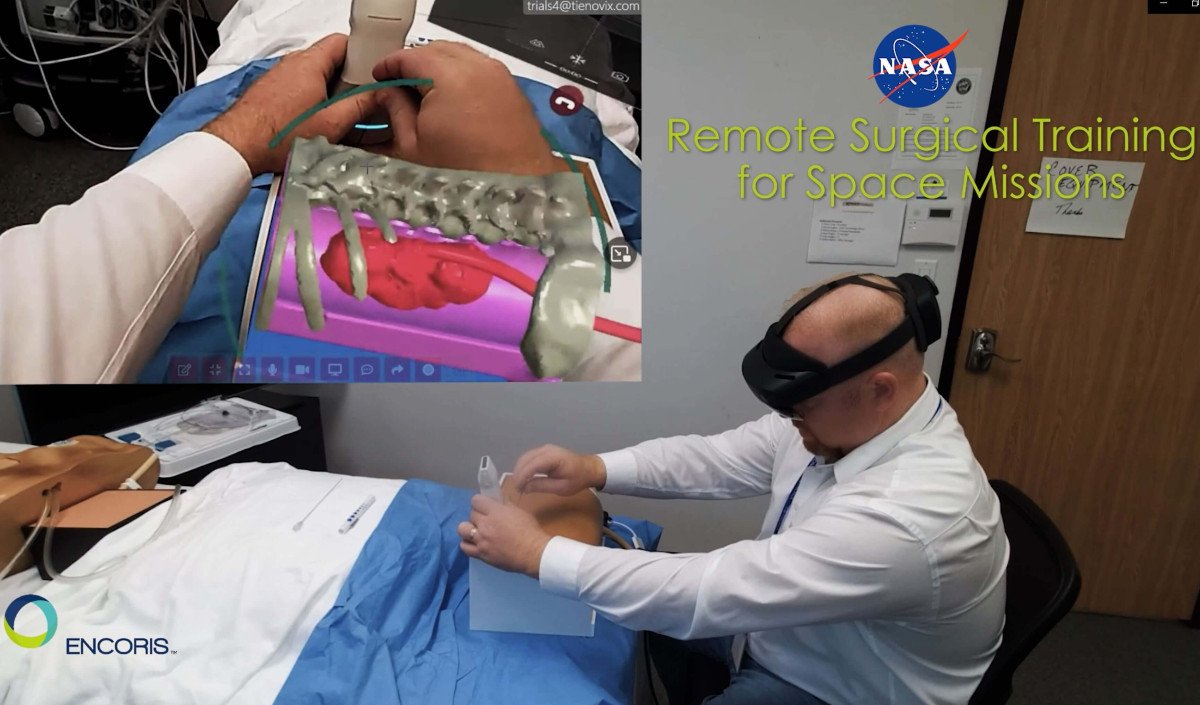

As minimally invasive surgical (MIS) innovation grows, Encoris uses cutting-edge manufacturing technologies to propel and satisfy 21st-century surgical training education demands.

- Embedded feedback sensory

- Customized pathology-specific anatomy

- Radiation-free X-ray imagery

- Augmented Reality (AR)

- Remote hands-on training

How Can We Help You Maximize Your Surgical Device Training Needs?

Fast, efficient communication and service with high-quality output and quick turnaround times. That’s the ENCORIS DIFFERENCE!

Surgical Education Contact Form

Surgical Training Simulation Benefits Orthopedic Device Companies and Their Technologies

The orthopedic market grew 3.5% in 2022 to a total of $55.5 billion in worldwide sales, according to our estimates. About 50 companies generated more than $100 million in sales that accounted for 84% of the market. The leading players in each segment helped return the industry to historical growth rates and drove innovation in the face of ongoing staffing shortages, supply chain challenges and inflation fears.

The Limiting Factors & Challenges of Cadavers

Cadavers are the primary means for orthopedic companies to develop and refine new surgical techniques and devices and have been around for centuries providing medical education value.

However, cadavers are limited in supply, now even worse due to Covid contamination. Their lack of suitable pathologies makes them inefficient. Their biohazards and need for fluoroscopy make using them incredibly limiting.

Given the vast inefficiencies that cadavers can pose as a surgical training medium, the use of simulated medical environments are becoming increasingly useful in the education of healthcare professionals.

Benefits of Surgical Simulation Training and Education

Bioskills simulators allow surgeons and product developers to more effectively test, evaluate, and practice the effectiveness of new implant procedures and instrumentation in a controlled environment before implementing them in live surgeries.

This iterative process can accelerate innovation and improve patient care outcomes.

From Encoris’ market standpoint, products that help drive surgical training efficiencies that cater to the delivery of better patient care are a win.

Other major benefits of using surgical simulation models for training:

- Cost savings. Companies can reduce the need for expensive cadaver and animal surgical training labs by providing trainees with more efficient simulators. Making surgical training more accessible and scalable can significantly reduce training costs and time.

- Standardizing surgical training methods. By providing a consistent platform, companies can ensure that all trainees receive uniform training and exposure to a wider range of orthopedic procedures. This standardization can enhance skill acquisition and surgical preparedness for live surgeries, reducing malpractice threats.

- Providing a controlled environment for surgical education. Surgical simulators allow trainees to practice specific orthopedic procedures repeatedly until they become proficient with new medical devices. This repetitive practice helps develop confidence and fine-tuning surgical techniques, leading to improved, faster surgical understanding.

How Can We Help You Maximize Your Surgical Device Training Needs?

Orthopedic companies benefit from using Encoris surgical simulation technology.

Encoris products offer a safer, cleaner learning environment, improve trainee proficiency, facilitate standardized training methods, aid in developing new surgical devices and techniques, and promote cost savings -Benefits that greatly enhance a company’s surgical education and training goals and the advancement of medical device technologies globally.

Encoris’ highly efficient manufacturing and streamlined communications processes help orthopedic companies like Stryker and Medtronic promote their medical device technologies with greater speed-to-market.

Encoris meets the demands of industry-leading global medical device providers; we’re confident in meeting your device promotion goals and surgical training objectives.